Q: Typical structure of the inner diameter lip of a deep groove ball bearing non-contact sealed bearing.

A: The two basic functions of the rolling bearing sealing system are to keep the lubricant inside the bearing and to prevent impurities from entering the bearing and the lubricant.

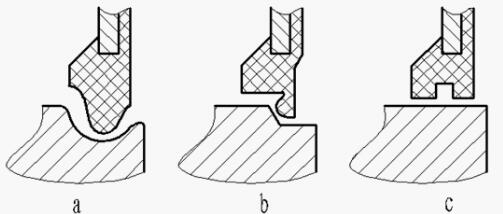

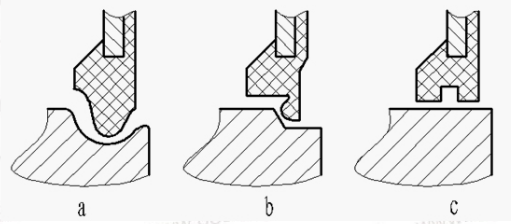

The sealing action must be realized between the relative motion surfaces (usually the shaft or the inner ring of the bearing and the bearing seat). The seal must not only adapt to the rotational motion, but also consider the eccentricity caused by runout, clearance, deflection, and deformation. The structural selection of the seal depends on the type of lubricant, and also the number and nature of the inclusions that must be excluded. The final selection depends on factors such as speed, friction, wear, working conditions, ease of replacement, and economy. The principle of sealed bearing design is to ensure that the sealing space is the largest after the seal ring or dust cover is installed on the base bearing. The typical structure of the inner diameter lip of a deep groove ball bearing non-contact sealed bearing is shown in the figure below.

Structure a is adopted by Japanese companies such as NTN and NSK. This seal adopts the principle of dynamic pressure sealing. When the bearing is running, it has a good effect of preventing external impurities from entering and preventing grease leakage. When the bearing stops running, it forms a static pressure curve seal with good sealing effect. However, it has high requirements for the sealing groove and is sensitive to the axial tolerance of the sealing groove and the axial clearance of the bearing.

Structure b is a structure that has been commonly used by some domestic manufacturers. It also forms a dynamic pressure seal, but the dynamic pressure effect will cause external impurities to enter the bearing, the sealing gap is short, and the effect is general.

Structure c is an optimized design. Its advantages are: avoiding the influence of axial tolerance and axial clearance, the grinding of the sealing surface improves the accuracy of the sealing pair, the groove-free inner ring rib reduces the processing cost, and the inner diameter of the sealing ring is a non-contact lip plus a grease retention groove. When the bearing has a tendency to leak grease, the overflowing grease stays in the groove, and the non-contact lip and the rib are sealed with grease, which improves the sealing performance.

The longer the sealing gap of the non-contact sealing pair, the smaller the gap amount, the better, but the length of the sealing gap is limited by the structure, and the gap amount is limited by the processing accuracy. The gap amount is determined by the gap parameters and is generally taken as 0.4~1.0mm in the diameter direction.

OUR COMPANY

HOW WE CAN MEET YOUR REQUIREMENTS. WE WILL FIND YOUR TAILOR-MADE BEARING SOLUTION.